The BMW S62 is one of BMW’s most durable engines, having powered multiple cars to Rolex 24 victories. Although enthusiasts conventionally cite rod bearings and vanos issues as weak points in the S62, neither is a regular cause of catastrophic engine loss. We at Partee Racing have been building S62s since 2016, and I cannot remember a single instance of a rebuild being triggered by a spun rod bearing. S62 vanos certainly malfunction and hence, cause engine malfunction, but never cause failure.

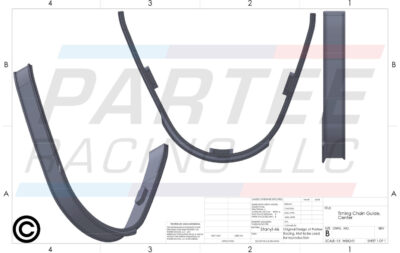

What IS a genuinely weak design point of the S62 and is REGULARLY responsible for catastrophic failure with S62s is the notorious “U-shaped” chain guide seen here:

As you can see, the brown plastic piece on which the S62’s main chain rides is clipped to the underlying aluminum piece six tinyclips on each side of the guide at the locations indicated above with arrows. Over time, these clips harden and break off, causing multiple maladies: First, the brown plastic material clogs the oil pump screen and impairs pump function. Second, and much more importantly, without the clips, the brown plastic rotates clockwise with the chain to the point where it sticks up above the aluminum backing and affirmatively interferes with the main chain and/or cam chains at the topof the engine. Finally, the space on the aluminum backing vacated by the rotated brown plastic directly contacts the chain, generating aluminum particles spread throughout the engine and inordinate strain on the main engine chain. At least 75% of the S62s we have rebuilt over the years have exhibited this malady.

The culprit, here, is of course the attachment method of the brown plastic to the backing piece. We at Partee Racing have spent months laboring over multiple modification options for the stock piece, but ultimately decided it simply needed to be redesigned from scratch. So that’s what we did.

The first and most important component of course is the replacement for the brown plastic. The first question: What material to use? The unanimous verdict was a particular grade of Stanyl 46, TW341, which is described as a “V2 UL-rated, non-reinforced high heat polyamide that offers excellent wear & friction properties in combination with outstanding creep resistance, strength, stiffness and fatigue resistance especially at high temperatures in combination with cycle-time advantages and excellent flow.” This is the latest material used by many automotive manufacturers for everything from gears to, you guessed it, chain guides.

With that settled, we needed a means of attaching the Stanyl 46 that would not slip, not move, and not break like the stock piece. Here is what we settled upon:

As shown, the redesigned Stanyl 46 guide has three “lugs” on the back of it that will fit tightly into the billet backing piece. There is no set of circumstances under which these lugs permit the entire guide to rotate out of position as the stock piece does. Moreover, while the friction fit of the Stanyl 46 really suffices to prevent it from coming off the billet backing, the billet backing will have corresponding lugs that abut the inside edge of the Stanyl 46 lugs and will be screwed into the Stanyl 46 lugs with M5 screws. Pins with a friction fit would suffice, but the screw provides a tighter fitment. Finally, because the screws will be installed from the side of the billet that abuts the engine block, there is no possibility of the screws backing out over time; they will be trapped between the face of the block and the back of the billet piece.

The billet piece will use the same connection points as the stock piece and will be CNC machined from a solid piece of 7075-T6 aluminum–a significant material upgrade from the cast aluminum stock piece.

We expect to make 500 of these in the initial run and should have the prototypes ready for testing in five or six weeks. We will install and test multiple prototypes on the engine dyno and in Partee Racing cars before posting for sale. Even before testing, however, we believe our redesigned U-shaped chain guide will be a lifetime part and pose no risk whatsoever of catastrophic engine loss as the stock piece does. Accordingly, we will be providing a lifetime warranty on this part.