Among the many myths floating around in the motorsport world is that engine blocks made from Alusil–an aluminum silicone alloy used in multiple BMW engines and many other brands, such as Audi–cannot be bored or honed, but rather, have to be sleeved to be used in a rebuilt motor. This is patently false and results either from ignorance or from the lack of knowledge and skill necessary to recondition Alusil cylinder walls.

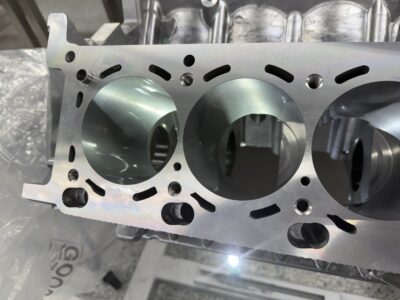

Alusil blocks can be bored and honed like any other. However, the boring and honing has to be followed by a final step: re-exposure of the silicone from the aluminum substrate. This is accomplished by etching away the aluminum, allowing finger-like projections of silicone to stand proud. These silicone fingers then provide a super smooth surface on which the piston rings ride, decreasing friction, heat and wear. And the space between the silicone fingers created by the removal of the aluminum becomes an enhanced repository for oil. These aspects–lower friction and heat and greater lubricity from additional oil-bearing capacity–comprise the functional beauty of an Alusil block.

It is this final step–reexposure of the silicone–of which shops either are ignorant or simply lack the expertise to perform. The process involves honing each cylinder using a non-automated honing machine with felt pads and special paste for a specific period of time and applying a particular pressure of the felt pads against the cylinder wall, as measured by the amperage pulled by the honing machine.

The cylinder wall is then cleaned with brake cleaner and its surface roughness is measured with a computerized profilometer. Only after the profilometer confirms that the requisite values for Ra, Rpk, Rvk, Mr1 and Mr2 have been obtained can one move on to the next cylinder.

The process is laborious and time-consuming but generates results that exceed the values exhibited by brand new BMW Alusil engine blocks. We have compared the surface roughness of brand new S62 blocks, and by each measure, our results are superior. And of course, because we use torque plates on both banks during all boring and honing operations, our reconditioned blocks do not exhibit cylinder wall distortion when the cylinder heads are torqued down. This is something that even BMW does not do. Thus, even when working with a new block from BMW, we hone it to first oversize and re-expose the silicone.

A word on sleeving: Many shops may understand the Alusil reconditioning process, but nevertheless eschew it as allegedly inferior to installing steel sleeves. Steel sleeves have radically different expansion and heat dissipation properties from Alusil and, thus, have to be fitted with great care and attention to detail lest they slip or expand in the wrong direction. But even when perfectly installed, steel sleeves will cause the engine to run materially hotter and do not strengthen an Alusil block, but rather, weaken it. The sole advantage to steel sleeves is their strength–ability to withstand high pressures–within the combustion chamber. Yet one of our clients runs one of our S62 reconditioned blocks with over 14 psi of boost and puts over 835 hp to the wheels in the racing context, so it is hard to imagine a case in which Alusil cylinder walls are insufficiently strong, even for forced induction. For these reasons, we strongly recommend against sleeving any Alusil block.

Partee Racing specializes in rebuilding Alusil-based BMW engines, including the S85, S65, S62 and M73. The minimum unit of work we do is a shortblock, in which we install our proprietary design pistons made for us by JE and designed specifically for the Alusil-based engines we build. If you have any questions about reconditioning Alusil cylinder walls, please reach out to me at peters@parteeracing.com.